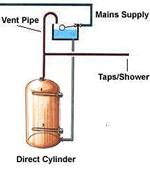

The first main feature to look for in a cylinder is the method in which the water is heated. Direct cylinders use electric immersion heaters to heat the water inside, and are typically used where no traditional heating system is available (such as flats or apartments).

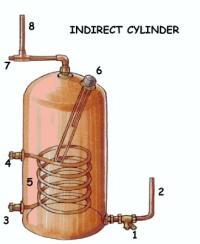

By contrast, indirect cylinders are heated via an external source (commonly a boiler, but solar panels are often used too). They typically have one or two coils located inside in which hot water from the central heating system is circulated through to transfer heat to the stored water inside. Indirect cylinders are the most common type found in heating systems as they often utilise the boiler to heat the stored water. Some Indirect Cylinders also feature an immersion heater to boost performance, allowing quicker heat up times.

Once the heating method has been decided, you then need to look at how the water is going to be distributed throughout your property to the hot water outlets (Taps, showers etc). This mostly depends on which type of boiler you have, so is very specific to your installation.

Vented, or Open Vented Cylinders are used in systems that feature a regular heat only boiler. Vented Cylinders require a header tank, which feeds cold water to the cylinders using a simple gravity fed method. The header tank is generally sited in the loft, with the cylinder installed directly below it.

Due to the fact that Vented Cylinders use Gravity to pass the water through the pipes of your hot water system, the pressure you receive at your outlets heavily depends on the distance between your header tank and the cylinder.

If you have a System Boiler at the heart of your heating system, then you’ll need an Unvented Cylinder to supply your hot water. Unvented Cylinders operate from the mains water pressure, and negate the need for a cold water feed (Header tank). Offering much higher hot water flow rates than their vented counter parts, Unvented Cylinders also free up space due to not requiring a header tank installation.

.png)